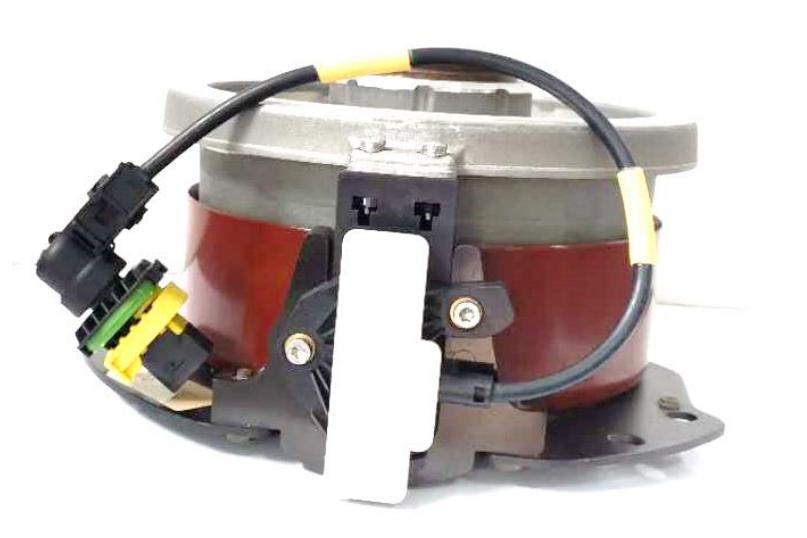

Clutch position displacement sensor(Transmitter)

description2

Feature

Apply

Basic parameter

Parameter |

Condition |

Induction principle |

Based on the linear Hall principle |

Operating voltage |

5±0.01 V |

Product characteristics |

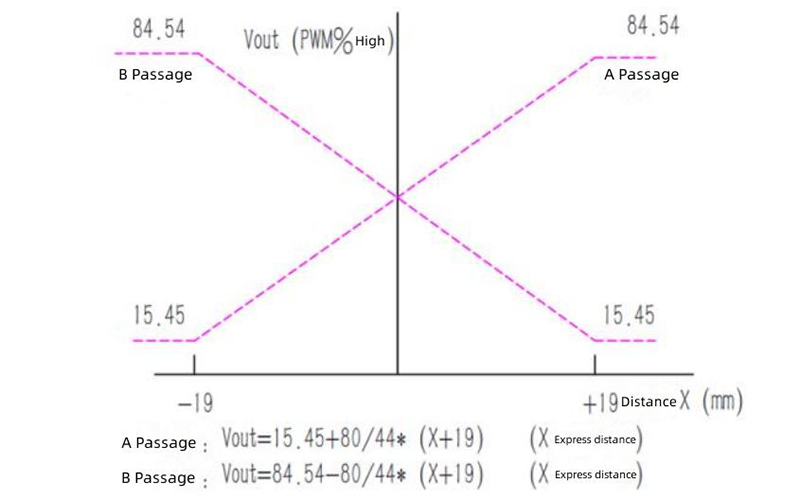

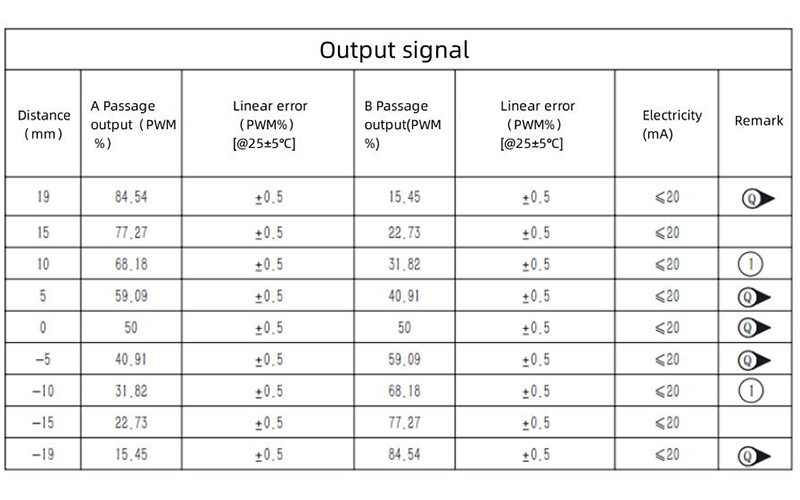

Normalized linear characteristic curves |

Wide range: 0~38mm | |

High accuracy: 1% (full range) | |

Customization: can customize the output analog voltage signal, PWM signal |

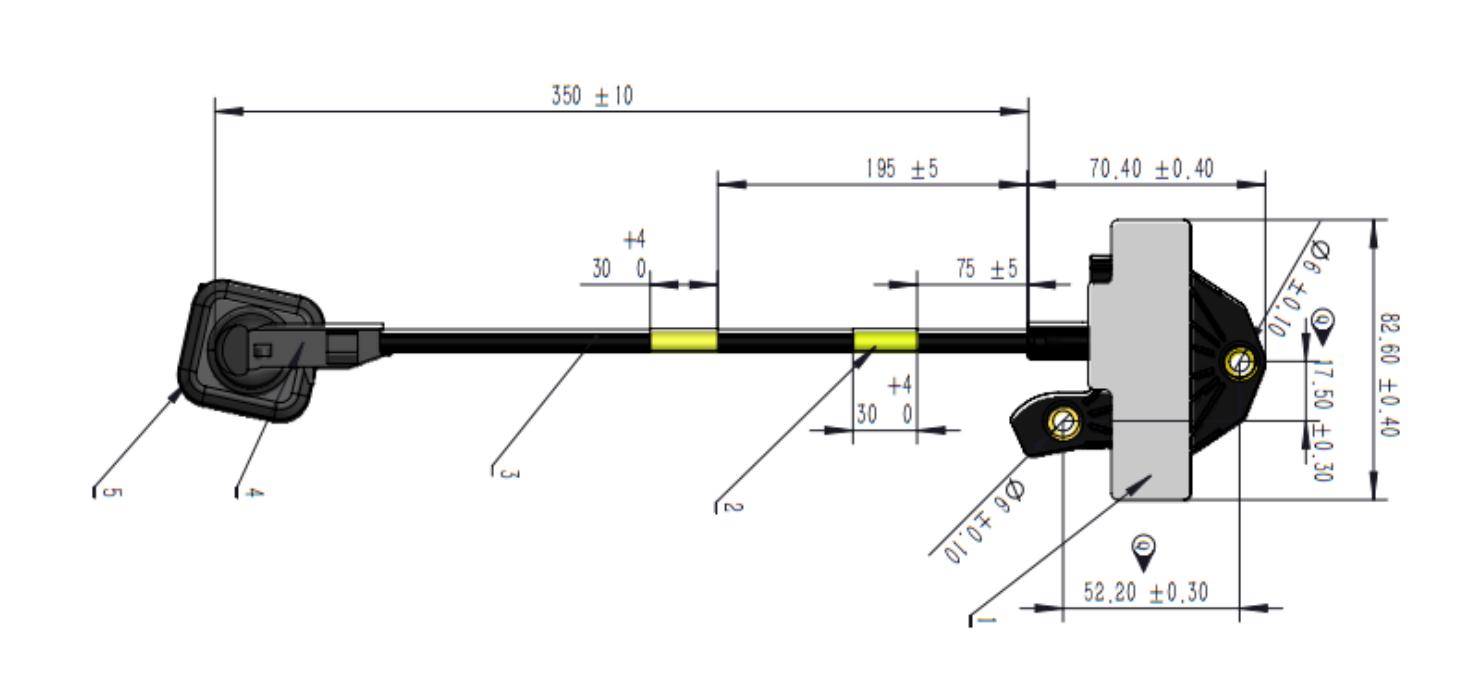

Mechanical dimension

Material Information

Number |

Name |

1 |

Sensor head |

2 |

Heat shrink tube |

3 |

lead |

4 |

Wire clamp |

5 |

sheath |

Installation position

Environmental test and reliability parameters

Number |

Test item |

Test condition |

Performance requirement |

Test standard |

1 |

Appearance inspection |

Test as follows: 1 Check whether there is any deterioration, deformation or excessive wear of injection parts and wires; 2 Use a microscope as needed to ensure the parts are intact; |

Meet the requirements of appearance standard |

Enterprise standard |

2 |

Insulation test |

The insulation resistance is tested as follows: 1 Test voltage: 500V; 2 Test time: 60s; 3 Test object: between terminal and housing; |

Insulation resistance ≥100MΩ |

Enterprise standard |

3 |

Withstand voltage test |

Test as follows: 1 Apply 50HZ, 550V AC voltage between the adjacent mutual insulation parts and the conductive body and the housing; 2 Hold for 1min; |

non-breakdown |

QC/T 413-2002

|

4 |

Functional test |

Test as follows: 1 5V±0.01V DC power supply; 2 Specific temperature: -40℃, 25℃,90℃, 125℃; 3 Each temperature point is stable for 1h; 4 Record the output signal of the same position at a specific temperature; |

At each temperature point, the difference at the same location is less than 1% |

Enterprise standard |

5 |

Overvoltage test |

Test as follows: 1 Working voltage: 15V for 60min; 2 Temperature: 25 ± 5℃; |

The product function is normal after the test |

Enterprise standard |

6 |

Reverse voltage test |

Test as follows: 1 Working voltage: reverse 5V voltage, lasting 1min; 2 Temperature: 25 ± 5℃; |

The product function is normal after the test |

Enterprise standard |

7 |

Low temperature resistance test |

Test as follows: 1 Place the product in a constant temperature and humidity box at -40℃ for 8h; 2 Working mode: normal working mode; |

After the product test, there is no crack on the surface of the plastic shell, and the function is normal during the test and after the test |

GB/T 2423.1, QC/T 413-2002

|

8 |

High temperature resistance test |

Test as follows: 1 Place the product in a constant temperature and humidity box at 125℃ for 8h; 2 Working mode: normal working mode; |

After the product test, the surface has no cracks and bubbles, and the function is normal during the test and after the test |

GB/T 2423.1, QC/T 413-2002

|

9 |

Resistance to temperature changes |

Test as follows: 1 Place at -40°C for 2 hours and at 125°C for 2 hours, the transfer time is less than 2.5 minutes, and the cycle is 5 times. 2 Working mode: normal working mode; |

After the product test, the surface has no cracks and bubbles, and the function is normal during the test and after the test |

GB/T 2423.22, QC/T 413-2002

|

10 |

Resistance to cyclic changes in temperature and humidity |

Test as follows: 1. 10 cycles of combined temperature/humidity cycle test were performed between -10℃ and 65℃; 2 Working mode: normal working mode; |

After the product test, the surface has no cracks and bubbles, and the function is normal during the test and after the test |

GB/T 2423.34, QC/T 413-2002, Enterprise standard

|

11 |

Flame retardant test |

Test as follows: 1 Small strip samples with a length of 127mm, a width of 12.7mm and a maximum thickness of 12.7mm were carried out in a non-ventilated test chamber; 2. Clamp the upper end of the sample (6.4mm) with a clamp on the support, and keep the vertical axis of the sample perpendicular; 3 The lower end of the sample is 9.5mm away from the lamp nozzle and 305mm away from the dry cotton surface; 4. Light the Bunsen burner and adjust it to produce a blue flame with a height of 19mm, place the flame of the Bunsen burner at the lower end of the sample, ignite it for 10s, then remove the flame (at least 152mm away from the test), and record the flame burning time of the sample; |

It meets the V-1 level, that is, after the sample is burned for 10s twice, the flame is extinguished within 60s, and no combustion can fall |

UL94

|

12 |

Water resistance (IPX 5) |

Test as follows: 1 Rotary speed: 5 ± 1 rpm; 2. Water spray distance: 100-150mm; 3 Water spray Angle: 0°, 30° 4 Water flow speed: 14-16 L/min; 5 Water pressure: 8000-10000 kPa; 6 Water temperature: 25 ± 5℃; 7 Water spraying time: 30s per Angle; 8 Working mode: normal working mode; |

Test process and post-test function Normal, no product after the test Margin, pressure resistance are normal

|

GB4208-2008

|

13 |

Chemical load test |

Test as follows: 1 Reagent: ⑴ gasoline; ⑵ engine oil; ⑶ transmission oil; ⑷ brake fluid; 2 Working mode: normal working mode; ③ Soak in the above oil products for 10 minutes; ④ Dry to dry at room temperature for 10 minutes; ⑤ 100℃ environment for 22h; |

No damage and deformation after test or color change, test process and test The post-test function was normal

|

GB/T 28046.5

|

14 |

Salt resistant fog |

Test as follows: 1 A salt spray cycle is 24h; 2 8h spray and standing for 16h; 3. Working mode: normal working mode; 4. Salt spray test cycle for 4 times; 5 Test temperature: 25 ± 5℃

|

The surface of the product has no rust after the test Erosion, during the test process and after the test normal function |

GB/T 2423.17, QC/T 413-2002, Enterprise standard |

15 |

vibration test |

Test as follows: 1 To fix the product on the vibration test table and be in the normal installation position 2 Working mode: normal working mode;

|

Outside the product after the test Crack, no loosening, test process And normal function after the test |

GB/T 2423.10

|

16 |

free fall test |

Conduct the test as follows: 1 Sample number: 3 samples 2. Number of drops per sample: 2 times; 3 Working mode: no work without electricity; 4 drop: 1m free fall; 5. Impact face: concrete ground or steel plate; 6 Drop direction: 3 samples have different axial drops, with the second drop and the first drop of each sample Drop to take the same axial different direction; 7 temperature:23±5℃. |

No invisible damage is allowed, In cases that do not affect the performance Lower, allow the shell to be small Damaged, post-test product function normal

|

GB/T2423.8

|

17 |

The plug and plug cycle of the connector |

Conduct the test as follows: The samples shall be tested at least 10 times at a constant speed of 50mm / min ± 10mm / min according to the product specifications. |

The connector is intact and the terminal is unchanged Form, power and signal transmission ordinary |

Enterprise standard

|

18 |

Coordination force of the connector

|

Conduct the test as follows: 1 fix the male end of the connector (with electric pump assembly) and the female end (with wire harness) with the positioning device; 2 insert the male end into the parent end socket at a constant speed of 50mm / min ± 10mm / min. |

The maximum coordination force shall be 75N

|

Enterprise standard |

19 |

Pull of the stuck connector put forth one's strength

|

Conduct the test as follows: The sample was fixed with a positioning device and applied with a constant speed of 50mm / min ± 10mm / min in the axial direction to record the pulling force. |

The pulling force of the stuck connector shall not be less than 110N.

|

Enterprise standard |