Pt200 high temperature EGT sensor

description2

Pt200 EGT sensor Features

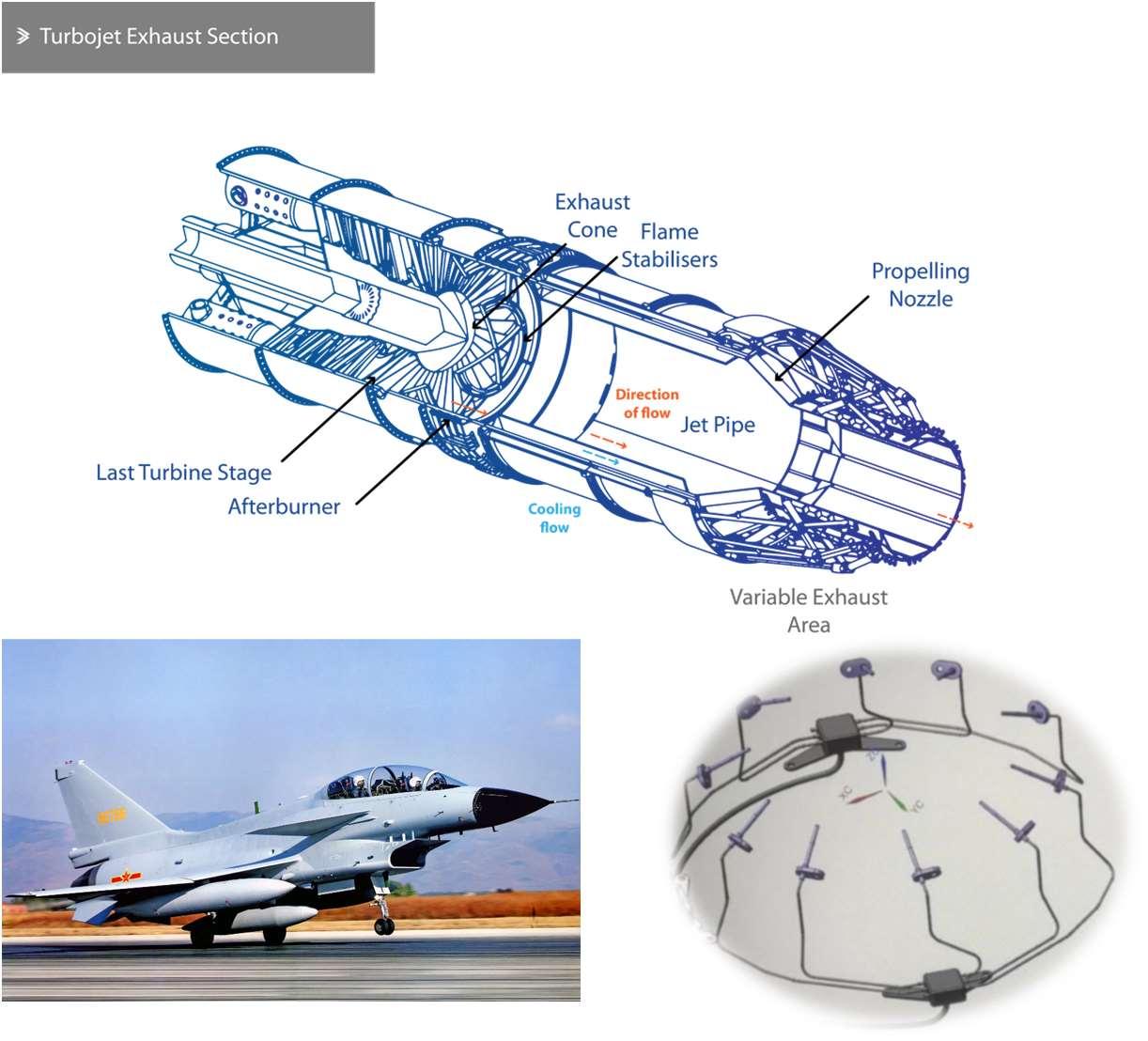

Application

*Military aircraft turbine outlet temperature monitoring

Features

Inductive property

parameter |

condition |

Chip type |

Pt200 Platinum resistance |

Induction principle |

Platinum-based electrical resistors have a positive temperature coefficient. The resistance of Pt200 platinum resistors will increase as the temperature increases. |

Nominal resistance |

200Ω@0℃ |

Operating temperature range |

-40℃~+850℃ Peak +900℃ |

Supply voltage |

5.0±0.1%V |

Pull-up resistor |

1KΩ±0.1% |

Working current |

2.6mA~4.3mA |

Accuracy |

±2.5℃@-40~+280℃ ±0.9%*T@+280~+900℃ |

Response time |

τ0.63<11s@300℃,Gas velocity 11m/s τ0.63<5s@300℃,Gas velocity 70m/s |

Insulation resistance |

>1MΩ@20℃,VDC500V |

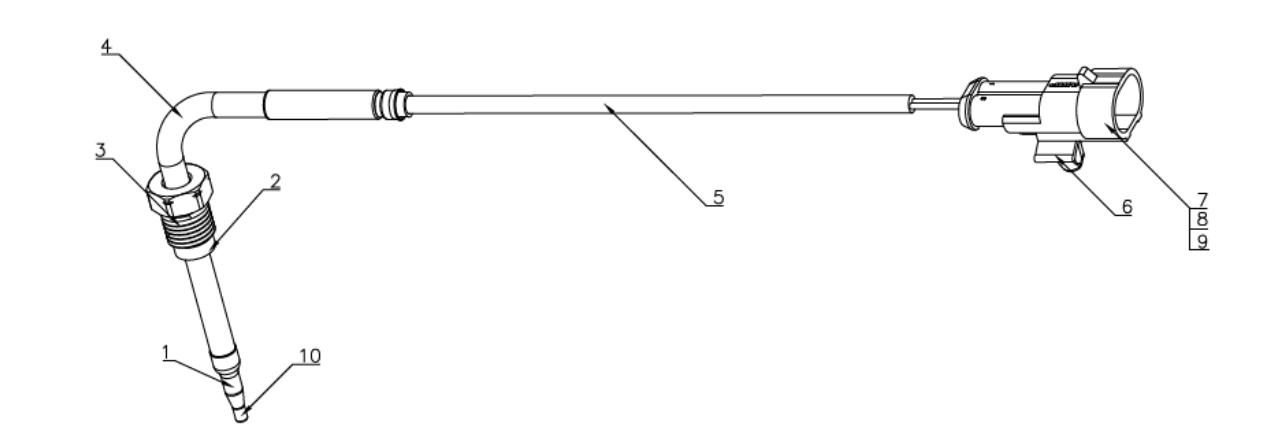

Material information

parameter |

specification |

1.Head special-shaped tube |

310S |

2.Flange |

310S |

3.Nut |

SUS316 |

4.Straight tube |

310S |

5.pencil |

Silicone rubber sheath, nickel-plated copper (fluoro rubber, teflon optional) |

6.Aircraft nose buckle (optional) |

TRW P/N#2823153810 (Customer can specify) |

7.Connector |

AMP P/N#C-282104-1 (Customer can specify) |

8.Terminal |

AMP P/N#C-282404-1 (Customer can specify) |

9.Lock card (optional) |

AMP P/N#C-281934-4 (Customer can specify) |

10.Chip |

Pt200 Platinum thermistor |

(The appearance of the above picture is for reference only)