High Temperature Exhaust Gas Treatment Differential Pressure Sensor

description2

Feature

Apply

Inductive property

Argument |

Conditions |

Operating temperature |

-40℃ ~ +135℃ |

Storage temperature |

-40℃ ~ +135℃ |

Working medium |

ail gas |

Working pressure |

(-1.7) ~ 34.5kPa (gauge) |

Overload pressure |

300kPa(g) |

Breaking pressure |

450kPa(g) (When the sensor is subjected to the failure pressure, the sensor is not required to be able to return to the normal working state, but the sensor must not break and leak under the failure pressure) |

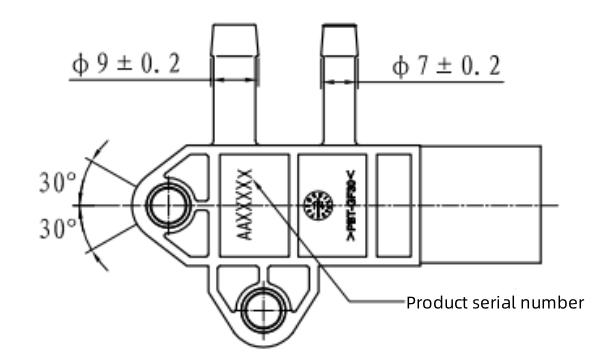

Mounting Angle |

+/-30° (installation Angle relative to vertical position (refer to drawings)) |

Supply voltage (Vcc) |

5.0±0.25V |

Supply current |

10mA MAX |

Overvoltage protection |

16V<1hour |

Normal temperature accuracy |

±1.2%Vcc @ 25℃ |

Total error band |

±2%Vcc (output error includes hysteresis error, repeatability error, linearity error and life drift error) |

Response time |

2ms MAX |

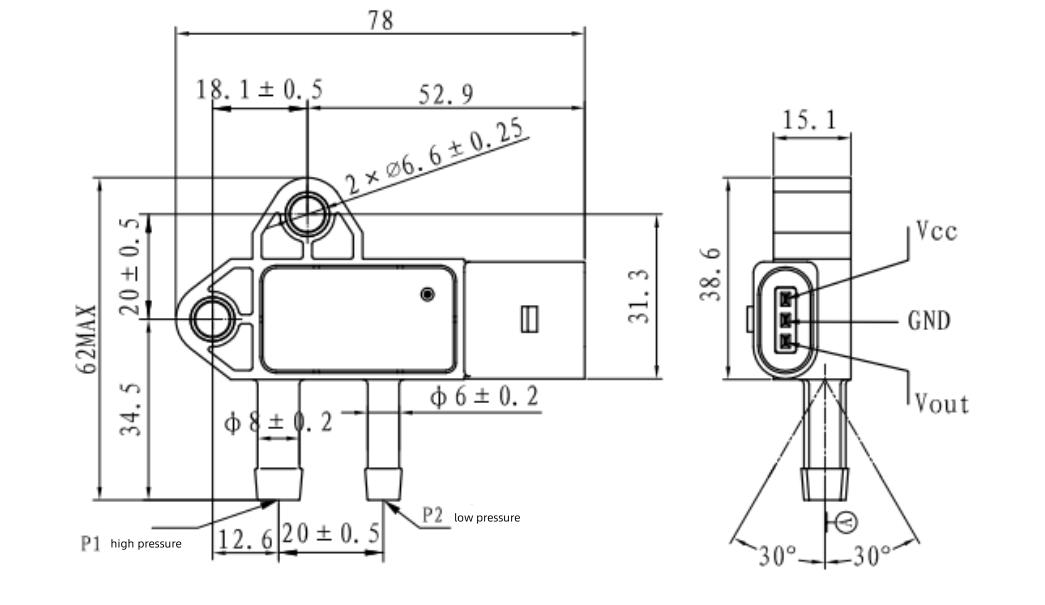

Mechanical dimensions

Environmental testing and reliability parameters

Number |

Test Item |

Test Conditions |

Performance Requirements |

1 |

Overload pressure |

Overload pressure :300kPa(g) Pressure time: 5min Test temperature: 20-25℃ |

After the sensor is restored to normal operation, it complies with the characteristics. |

2 |

Destruction pressure |

Burst pressure :450kPa(g) Pressure time: 1min Test temperature: 20-25℃ |

When the sensor is subjected to the failure pressure, the sensor is not required to be able to return to the normal working state, but the sensor cannot be damaged and leaked under the failure pressure. |

3 |

Pressure temperature cycle |

he temperature cycle is -40℃~135℃ The pressure cycle is -1.7~34.5kPa Hold for 84h and maintain for 0.5 hours at each pressure limit point and temperature point |

All sensors should meet the accuracy requirements after testing and there should be no leakage. |

4 |

Low temperature storage |

Test temperature: -40 ℃

Test time: 72 hours |

All sensors should meet the accuracy requirements after testing and there should be no leakage. |

5 |

High temperature storage |

Test temperature: 135 ℃ Test time: 72 hours |

All sensors should meet the accuracy requirements after testing and there should be no leakage. |

6 |

Thermal Shock |

Low temperature: -40 ℃ High temperature: 135 ℃ Cycle count: 500 Cycles Holding time for each temperature point: 1 hour The sensor is not powered on during the experiment. |

All sensors should meet the accuracy requirements after testing and there should be no leakage. |

7 |

Temperature and humidity cycle |

The humidity chamber with the initial temperature of +23℃ and the initial humidity of HR83% was heated to +40℃ within 5h, and the humidity was raised to HR92%, and kept for 12h; After 5h, the temperature was lowered to +23℃, and the humidity was HR83% for 2h. The above process was repeated 21 times for 504h. The sensor is not powered up during the experiment. |

All sensors should meet the accuracy requirements after testing and there should be no leakage.

|

8 |

Durability test |

Pressure cycle at high temperature 110 +/-5℃ : from -1.7kPa to 34.5kPa, frequency is 0.5Hz; The number of cycles is 2 million. The sensor is not powered up during the experiment. |

All sensors should meet the accuracy requirements after testing and there should be no leakage.

|

9 |

Fluid compatibility test |

The sensor is connected to an electrical harness and a 5V power supply is applied. The four reagents in the figure below are tested separately. Test method: Drop 5-10 drops of reagent onto the pressure interface of the sensor as shown in the following figure (The air inlet direction is upward), and then the sensor is placed in a temperature box at 100 ° C for 2 hours. After rinsing, repeat the test with the other three reagents. number Type experiment quantity 1 diesel 5 drops 2 Engine oil 10 drops 3 gasoline 10 drops 4 glycol 10 drops |

All sensors should meet the accuracy requirements after testing

|